Overhead crane reducer: how to improve work efficiency and extend life

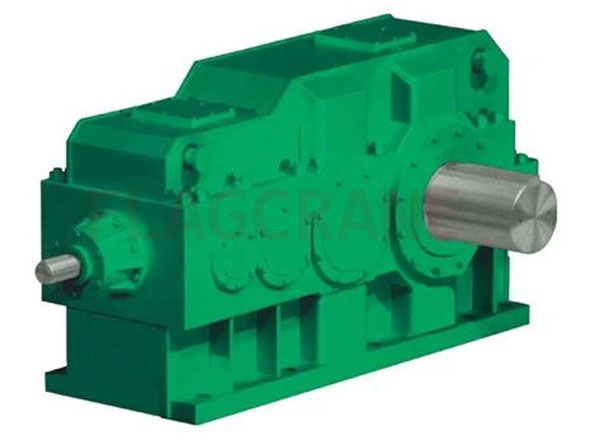

The overhead crane reducer is an important part of the overhead crane, which is mainly responsible for converting the high-speed rotation of the motor into low-speed and high-torque output, so as to achieve the smooth operation of the crane. As a key component of power transmission, the reducer not only affects the operating efficiency of the equipment, but is also closely related to its service life and failure rate.

The role of the reducer

In the overhead crane, the reducer increases the output torque by reducing the speed, so that the crane can lift heavy objects accurately and stably. Its main function is to ensure the smooth transmission of the power system, reduce the load of mechanical equipment, and control the lifting speed to ensure safe operation.

Type analysis

The reducer can be divided into many types according to its structure and function. Common ones include worm gear reducer, planetary gear reducer, cylindrical gear reducer, etc. Worm gear reducer is often used in occasions with large loads and has good reduction ratio and stability; planetary gear reducer is suitable for high-speed operation and has the advantages of high efficiency and compactness. Each reducer has its specific application scenario, and the appropriate reducer type should be selected according to the actual working conditions.

Troubleshooting

Common faults of reducers during use include gear wear, bearing damage, oil leakage, etc. Gear wear may cause increased noise or unstable transmission, while bearing damage will affect the stability of the reducer. Oil leakage will not only damage the equipment, but also cause safety problems. Regular inspection and maintenance, and timely replacement of damaged parts are effective ways to avoid failures.

Optimization and maintenance

In order to improve the working efficiency of the reducer and extend its service life, correct use and maintenance are essential. First, the load should be reasonably applied according to the design specifications of the reducer to avoid overload operation. Secondly, regularly check the use of lubricating oil to ensure the normal operation of the lubrication system. At the same time, keep the equipment clean to prevent foreign matter from entering the reducer to reduce friction and wear. Finally, follow the maintenance guidelines provided by the manufacturer for regular maintenance and repairs.

By correctly selecting and maintaining the reducer, not only can the working efficiency of the overhead crane be improved, but also the service life of the equipment can be effectively extended and maintenance costs can be reduced.